Manufacturing in Indiana is the backbone of the state’s economy – but it also comes with some of the toughest compliance challenges. Between OSHA requirements, DOT regulations, and the growing need for workforce health programs, leaders are under pressure to protect both their people and their production lines. For many employers, drug testing is one of the most critical – and complex – pieces of the compliance puzzle.

Whether you’re an HR professional, safety officer, or executive decision-maker, this guide is built for you. Download your copy today and get the Indiana-specific roadmap to smarter compliance and healthier, more productive teams.

The Indiana Manufacturer’s Guide to Workforce Health Compliance: Drug Testing, Safety, and Workforce Readiness is your playbook for navigating these challenges with confidence. Inside, you’ll find:

- A clear overview of federal and Indiana-specific regulations that impact manufacturers

- Practical checklists for drug testing, physicals, and immunizations

- Insights into current drug trends (opioids, THC, and more) that affect your hiring and retention strategies

- Real-world examples of what compliance gaps cost manufacturers in fines, downtime, and lost contracts

- Proven strategies for streamlining testing, automating compliance documentation, and building a safer, more reliable workforce

By the end, you’ll not only understand the risks of falling behind on compliance – you’ll have actionable steps to strengthen your safety culture, protect margins, and keep your operations moving without costly disruptions.

Download the Whitepaper

The Compliance Landscape in Indiana Manufacturing

Why Compliance is Non-Negotiable

Indiana has one of the strongest manufacturing sectors in the country, employing over half a million workers. With such a large workforce in safety-sensitive environments, compliance with occupational health regulations isn’t just about passing inspection – it’s about protecting lives, productivity, and contracts.

For Indiana manufacturers, compliance sits at the intersection of three forces: federal oversight (OSHA/DOT), state-specific requirements, and customer/contract expectations.

OSHA Requirements Every Manufacturer Should Know

- General Duty Clause: Employers must provide a workplace free from recognized hazards.

- Recordkeeping: OSHA requires accurate logs of workplace injuries and illnesses.

- Hazard-Specific Standards: From noise levels to chemical exposures, OSHA standards directly impact health screenings and medical surveillance programs.

- Post-Incident Obligations: After accidents, drug and alcohol testing often comes into play for compliance and liability reasons.

Indiana operates under its own OSHA program (IOSHA), which mirrors federal OSHA but occasionally adopts stricter enforcement practices.

The Compliance Landscape in Indiana Manufacturing

DOT Regulations That Hit Manufacturing

Many Indiana manufacturers operate fleets or employ CDL drivers, making DOT compliance a constant priority:

- Drug & Alcohol Testing: Pre-employment, random, reasonable suspicion, and post-accident testing are all required under DOT.

- Medical Exams & Certifications: Drivers must pass regular DOT physicals to maintain medical cards.

- Record Retention: Documentation must be organized, accessible, and audit-ready – gaps can trigger heavy penalties.

The Role of Drug Testing in Compliance

- Safety risks on the shop floor

- Costly shutdowns due to preventable accidents

- Lost contracts if customers or suppliers require proof of a drug-free workforce

Drug testing isn’t just a box to check. For Indiana manufacturers, it’s often the first line of defense against:

- With cannabis legalization in neighboring states and rising opioid concerns, Indiana employers face increasing pressure to keep policies updated and defensible.

Key Takeaway

Compliance for Indiana manufacturers isn’t just about staying “within the law” – it’s about building a resilient workforce that keeps operations running smoothly. OSHA, DOT, and drug testing requirements form the foundation of that strategy.

The State of Drug Testing in Manufacturing

DOT Regulations That Hit Manufacturing

Drug testing is a cornerstone of workforce compliance in manufacturing, where safety-sensitive roles and heavy machinery heighten risk. For Indiana employers, testing programs are not only required under federal and DOT standards but are also a practical safeguard against costly accidents and downtime. Nationally, nearly two-thirds of U.S. employers maintain some form of workplace drug testing program, with manufacturing among the most consistent sectors to do so (Current Consulting Group, 2022).

Types of Drug Testing in Manufacturing Workforces

Manufacturers typically rely on a combination of testing strategies:

- Pre-Employment Testing: Ensures new hires are fit for safety-sensitive work before stepping onto the shop floor.

- Random Testing: Acts as both deterrent and detection, required under DOT regulations for CDL drivers and often extended to broader workforce roles.

- Post-Incident/Reasonable Suspicion Testing: Triggered by workplace accidents or observable impairment, providing both liability protection and a safety check.

- Return-to-Duty & Follow-Up Testing: For employees returning after a violation or treatment program, ensuring readiness and compliance (U.S. Department of Transportation, 2024).

The State of Drug Testing in Manufacturing

Substance Trends Impacting Employers

Indiana manufacturers are contending with shifting substance use patterns:

Opioids: Indiana has historically been among the states hardest hit by the opioid crisis, with more than 2,700 overdose deaths in 2021 (Indiana Department of Health, 2022). This reality spills into workplaces, creating increased risks of impairment.

Cannabis: Though marijuana remains illegal in Indiana, surrounding states like Michigan and Illinois have legalized recreational use. This creates legal and policy gray areas for Indiana employers, especially with job applicants crossing state lines (National Conference of State Legislatures [NCSL], 2024).

Amphetamines & Stimulants: Nationwide testing data shows a steady increase in amphetamine positives, with Quest Diagnostics’ Drug Testing Index reporting double-digit rises since 2017 (Quest Diagnostics, 2023).

Common Pitfalls in Drug Testing Programs

Even manufacturers with strong programs face challenges that undermine compliance and efficiency:

- Delays in Results: Long turnaround times can leave roles unfilled, slowing production.

- Poor Documentation: Missing chain-of-custody records or disorganized result tracking can cause issues in OSHA/DOT audits or contract reviews.

- Over-Reliance on Paper Processes: Manual paperwork increases the risk of errors and drains HR bandwidth.

Key Takeaway

For Indiana manufacturers, drug testing is more than a compliance requirement – it’s a frontline defense against workforce disruption. But without modernized systems, testing programs can create their own bottlenecks.

Employers who balance robust testing protocols with efficient technology and communication will be best positioned to safeguard both people and productivity.

The Cost of Getting it Wrong

Compliance Gaps = Real Business Risks

Non-compliance in workforce health isn’t theoretical. For Indiana manufacturers, missing a single step – like delaying a pre-employment drug test or failing to document a random screening – can cascade into fines, lost productivity, and even terminated contracts.

- Regulatory Penalties: OSHA penalties can exceed $15,000 per violation, with willful or repeated violations climbing past $156,000 (Occupational Safety and Health Administration [OSHA], 2024). DOT violations can add thousands more per instance, especially for drug and alcohol testing lapses (Federal Motor Carrier Safety Administration [FMCSA], 2024).

- Operational Disruptions: A single impaired worker can trigger accidents, injuries, and machine downtime. The National Safety Council estimates that workplace injuries cost U.S. employers more than $167 billion annually in medical expenses, lost productivity, and administrative costs (National Safety Council [NSC], 2023).

- Contract & Reputation Losses: Large manufacturers and suppliers increasingly require proof of compliance from partners. Failure to demonstrate a robust testing and safety program can disqualify a company from bids or lead to early contract termination.

- Hidden Costs of Delays: Even without accidents, slow drug screening processes stall hiring pipelines. In a labor market already strained by high turnover, delays translate directly into production slowdowns and overtime costs.

In 2022, an Indiana manufacturing firm was fined after failing to properly document post-incident drug testing following a forklift accident. Beyond OSHA’s $20,000+ fine, the company reported over $100,000 in lost productivity during the downtime and corrective actions (Indiana Department of Labor, 2023).

Turning Compliance Into a Competitive Advantage

Compliance doesn’t have to be a burden. When managed effectively, it becomes a key driver of operational efficiency, employee trust, and brand credibility. Forward-thinking Indiana manufacturers are using modern tools and smarter workflows to transform drug testing and workforce health into productivity boosters – not paperwork nightmares.

1.) Streamline Testing with Connected Provider Networks

Coordinating tests across multiple locations or shifts can be chaotic. Manufacturers can eliminate bottlenecks by partnering with occupational health platforms that offer national provider networks and digital scheduling.

- Clinics with real-time availability reduce missed appointments and rescheduling delays.

- Automated result delivery ensures HR and safety managers receive verified reports without manual chasing.

- Centralized dashboards make compliance audits nearly effortless.

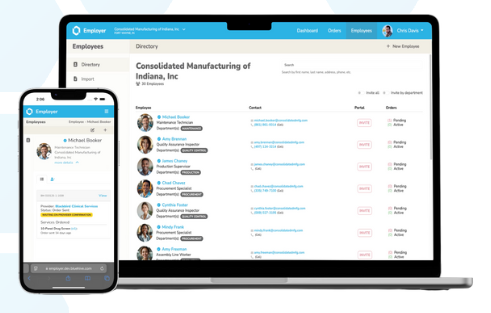

Platforms like BlueHive help manufacturers tap into over 20,000 provider sites nationwide, ensuring consistent access for pre-employment, random, and post-incident screenings.

2.) Automate Documentation and Recordkeeping

Manual logs are a recipe for error and stress – especially when facing an audit. Digital systems that integrate chain-of-custody forms, lab results, and physical exam records cut admin time dramatically and reduce risk of misplaced paperwork.

- Automated alerts for renewals or missing results keep HR teams proactive.

- Electronic recordkeeping simplifies DOT and IOSHA audit prep.

- AI tools can even detect anomalies or incomplete files before they become violations.

3.) Strengthen Randomization and Policy Consistency

Random drug testing is one of the most effective deterrents – but only if done fairly and consistently.

- Use software-generated randomization to avoid bias and maintain transparency.

- Document policy enforcement uniformly across departments to prevent grievances.

- Communicate policies clearly so employees understand expectations and consequences.

4.) Build Strong Communication Channels

Compliance success isn’t just about systems – it’s about people. Manufacturers that communicate testing processes clearly, provide support for employees navigating requirements, and celebrate safety milestones foster a stronger safety culture overall.

- Regular “safety and wellness” updates keep compliance front-of-mind.

- Offering confidential employee support (like substance recovery resources) can reduce turnover and improve morale.

Building a Safer, More Reliable Workforce

Compliance That Pays Off

For Indiana manufacturers, compliance investments often start as a cost center – but they end up driving measurable returns. Organizations with robust health and drug testing programs experience fewer accidents, lower turnover, and stronger financial performance. In fact, the Occupational Safety and Health Administration (OSHA) estimates that for every $1 invested in workplace safety, employers can save between $4 and $6 in avoided injuries, downtime, and insurance costs (OSHA, 2024).

Beyond cost savings, proactive compliance enhances operational reliability. Reduced absenteeism, consistent staffing, and higher morale translate into smoother production and fewer disruptions. When employees trust that their employer values safety, engagement levels rise – a win that shows up both in productivity metrics and retention numbers (National Safety Council [NSC], 2023).

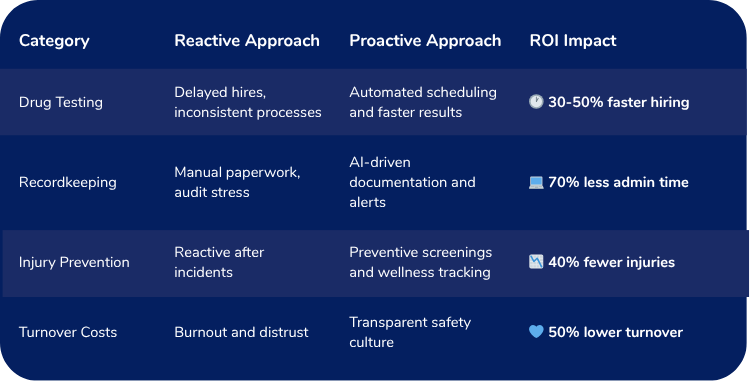

The Financial ROI of a Strong Compliance Program

When compliance systems are automated and transparent, employers spend less time reacting to problems—and more time growing their business.

The Cultural ROI: Safety as a Shared Value

Numbers tell one part of the story; people tell the rest. Proactive compliance programs also cultivate a culture of trust and accountability:

- Employees feel safer and more valued when processes are consistent and fair.

- Transparency about drug testing and health protocols reduces anxiety and stigma.

- A reputation for safety and integrity helps attract skilled workers – a major advantage in Indiana’s competitive labor market.

The Takeaway

Compliance isn’t just protection – it’s performance. By investing in digital tools, clear communication, and a culture that values safety, Indiana manufacturers can achieve a powerful ROI: fewer accidents, happier employees, and stronger profit margins.

Turning Compliance into a Competitive Edge

From Burden to Breakthrough

For Indiana manufacturers, compliance isn’t just about passing inspections – it’s about building resilience. The companies that treat drug testing, physicals, and safety protocols as strategic investments aren’t just reducing risk; they’re fueling productivity, loyalty, and long-term growth.

In a landscape shaped by evolving OSHA and DOT standards, a tightening labor market, and increasing customer expectations, the difference between reactive and proactive compliance is the difference between treading water and leading the pack.

Modern occupational health platforms like BlueHive make that transformation possible. With automated notifications, an integrated provider network, and centralized platform, BlueHive helps manufacturers stay compliant, reduce administrative stress, and keep their workforce healthy and ready for the demands of production.

Sources

- Current Consulting Group. (2022). 2022 Employer Drug Testing Survey [PDF]. Retrieved from https://www.currentconsultinggroup.com/wp-content/uploads/2022/11/2022-Employer-Drug-Testing-Survey-Slick.pdf

- Federal Motor Carrier Safety Administration. (n.d.). Drug & alcohol testing program. Retrieved from https://www.fmcsa.dot.gov/regulations/drug-alcohol-testing-program

- Indiana Department of Health. (2022). Drug overdose prevention: Indiana data. Retrieved from https://www.in.gov/health/overdose-prevention/

- Indiana Department of Labor, Division of Occupational Safety and Health (IOSHA). (n.d.). IOSHA Home / About IOSHA. Retrieved from https://www.in.gov/dol/iosha/iosha-home/

- Indiana Department of Labor, Industrial Compliance. (n.d.). Industrial Compliance — IOSHA. Retrieved from https://www.in.gov/dol/iosha/industrial-compliance/

- Indiana Department of Labor, Indiana Occupational Safety Standards Commission. (n.d.). IOSSC overview. Retrieved from https://www.in.gov/dol/iosha/indiana-occupational-safety-standards-commission/

- Indiana Department of Labor, Safety Orders. (n.d.). IOSHA Safety Orders. Retrieved from https://www.in.gov/dol/iosha/iosha-safety-orders/

- National Conference of State Legislatures. (2024). State medical cannabis laws. Retrieved from https://www.ncsl.org/health/state-medical-cannabis-laws

- National Safety Council. (n.d.). Work injury costs. Injury Facts. Retrieved from https://injuryfacts.nsc.org/work/costs/work-injury-costs/

- Occupational Safety and Health Administration. (2024). OSHA penalty amounts and cost-benefit of compliance. Retrieved from https://www.osha.gov/penalties

- Quest Diagnostics. (2023). Drug Testing Index 2023: Data tables [PDF]. Retrieved from https://www.questdiagnostics.com/content/dam/corporate/restricted/documents/employer-solutions/2023-drug-testing-index-and-industry-insights/Drug-Testing-Index-2023-Data-Tables-20230511.pdf

- U.S. Department of Transportation. (2024). Drug and alcohol testing regulation updates. Retrieved from https://www.transportation.gov/odapc